In the world of advanced materials, the intersection of strength, aesthetics, and sustainability marks the frontier of innovation. Among the emerging leaders in this space is Sodiceram, a high-performance ceramic material and brand that seamlessly blends sodium-based compounds with modern design and industrial functionality. Known for its exceptional mechanical properties, thermal resilience, and chemical resistance, Sodiceram is increasingly being adopted across architectural, industrial, and decorative applications. More than just a ceramic product, Sodiceram represents a new paradigm in material science — one that prioritizes durability, design versatility, and eco-conscious manufacturing.

What Is Sodiceram?

Sodiceram is a sodium-enhanced ceramic material developed for demanding environments and sophisticated design needs. Its defining feature is the integration of sodium-based compounds into the ceramic matrix, which improves the material’s mechanical strength, thermal stability, and resistance to chemical corrosion. This unique formulation not only elevates the performance of the ceramic under stress but also expands its functional and aesthetic versatility.

Whether it’s used as architectural cladding, industrial components, or decorative surfaces, Sodiceram delivers a robust yet elegant solution. Beyond its technical attributes, Sodiceram is also renowned for its commitment to sustainability, offering products made with recycled materials and energy-efficient processes. The incorporation of advanced surface technologies such as digital printing, laser engraving, and 3D texturing further distinguishes Sodiceram in a competitive market.

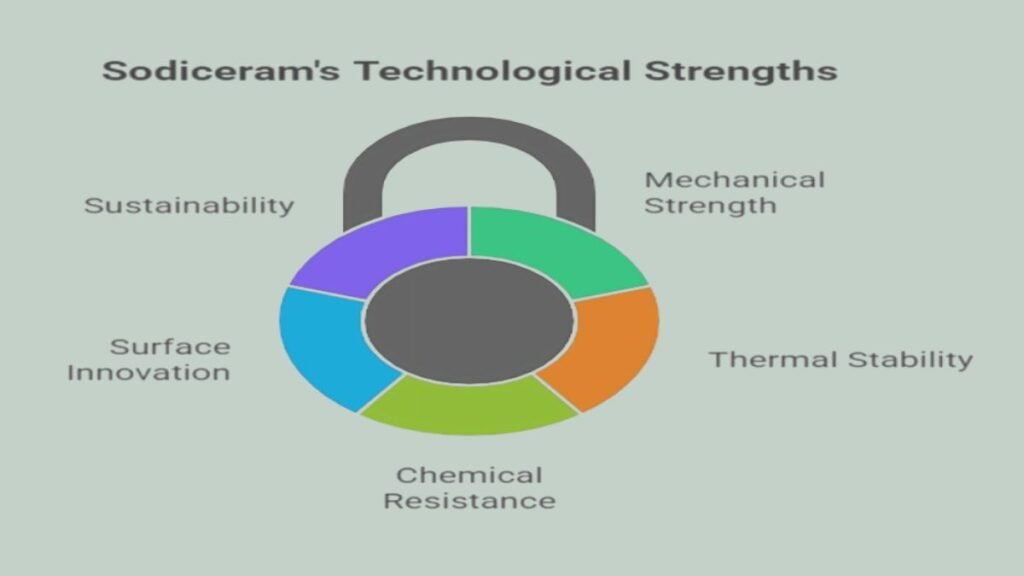

Key Properties and Technological Strengths

1. Increased Strength Mechanical

The compounds found in Sodiceram which is made up of Sodium enhance flexibility and enhanced strength under flexural and compressive loads. The material is therefore perfect in applications such as flooring, cladding as well as in structural materials, which require a long lasting material with high impact resistance.

2. High Thermal Stability

It has been created with the capacity to resist high temperatures without deforming or melting, which therefore makes it suited in places where its surrounded by a lot of temperature variations. It particularly comes in handy in industrial kilns, fireplaces, and external surfaces where direct sunlight is exposed to.

3. Resistance to Chemical and Stains

Chemical, stain and water resistance of Sodiceram is one of the most convincing features of the product. It is also inert to most solvents, acids and alkalis and is therefore long lasting and needs little maintenance, particularly when used in kitchens, labs and out doors installations.

4. Surface Innovation: 3D Texturing Digital Printing

It has advanced manufacturing where the use of high-definition digital print and complicated 3D textures are possible. These can even make architects and designers reproduce natural stones, wood, and abstract patterns with amazing authenticity and touch impressiveness.

5. Eco-Conscious Manufacturing and Sustainability

The manufacturing process of Sodiceram draws on recycled materials and energy-saving kilns, recycling water, and recycling programs. This puts the product in line with the green building specifications like LEED and BREEAM and meets the preference of the environmentally friendly projects.

Applications Across Sectors

1. Architectural Use

It has been widely used in building work (interior and exterior). Its strength and visual versatility allows its use in floor tiles, wall claddings and facades, and counter tops. It is durable even in commercial areas with a lot of traffic and has a sleek modern appearance.

2. Industrial Applications

In the case of the industrial sectors, it is appreciated due to its heat, pressure, and chemical resistant properties. It finds application in industrial plants, in laboratories and in work areas where it has to be used under strenuous conditions.

3. Decorative Installations

Sodiceram is also popular as a medium for decorative applications because it can be textured, colored and high fidelity printed. It is used to make art installations more beautiful, feature walls intact, designer bathrooms and luxurious kitchen space.

4. Urban Infrastructure

Sodiceram paves outdoor pavements, subway stations, and public places in the city, with a functionality and a luxurious appearance. Its immunity to weathering and vandalism also contribute to its usage in the public infrastructure.

Design Versatility: Bridging Form and Function

The capacity to adjust to diverse design needs is also one of the bright aspects of Sodiceram. Sodiceram unlike conventional ceramics with their limited finishing and shapes embraces latest state of art technologies such as:

- High-Definition Digital Printing: The ability to create realistic images and patterns on ceramic and include marble-like veining, rustic wood grain and abstract art patterns.

- 3D Surface Texturing: This gives a feel to the touch which improves grip and aesthetic appearance. This is especially of great importance in anti-slip flooring and feature wall construction.

- Large Format Tiles: These decrease grout joints and provide a smooth, wide appearance, perfect in contemporary minimalist building.

Environmental Stewardship and Sustainable Impact

In today’s environmentally conscious world, the manufacturing footprint of building materials is under intense scrutiny. Sodiceram addresses these concerns head-on by incorporating sustainable practices throughout its production cycle:

- Recycled Raw Materials: Sodiceram uses a high percentage of recycled content in its ceramic blends, reducing the demand for virgin resources.

- Energy-Efficient Kilns: Advanced kiln technology reduces energy consumption and emissions during firing, a traditionally energy-intensive process.

- Water Management: Closed-loop water systems minimize water usage and eliminate contamination.

- Low VOC Emissions: Finished Sodiceram products emit negligible levels of volatile organic compounds, promoting healthier indoor air quality.

Comparative Advantage: Sodiceram vs Traditional Ceramics

| Feature | Sodiceram | Traditional Ceramic |

| Mechanical Strength | High | Moderate |

| Thermal Stability | Excellent | Moderate |

| Chemical Resistance | Superior | Limited |

| Design Flexibility | High (3D, digital printing) | Basic finishes |

| Sustainability | Strong focus (recycled, low energy) | Variable |

Future Outlook

The future of Sodiceram is based on consistent innovation. There is research and development being undertaken that is involved in incorporating even higher nano materials that are self-cleaning, added UV resistance and antimicrobial. The firm is also working on customization systems that will enable the clients to design and have their custom made ceramic finishes done to absolute specification.

It is also expected that the company will expand to conquer new markets and sectors like the healthcare setting, aerospace, and high-tech electronics since there is an increasing demand of durable, safe, and environment-friendly materials.

Conclusion

The one after ceramic is the sodiceram; a technologically newer concept of ceramics that presents an impressive array of strength, beauty, and eco-friendliness. The high-performance, sodium-enhanced version is able to improve performance to challenging circumstances rather than just high temperature and pressure, but can also enable exceptional design capabilities. Sodiceram has unlimited dynamic applications, both in an industrial environment and an upscale residential establishment, performing equally well at all times.

Visit our blogs for more!

James Whitaker brings a wealth of knowledge and creativity to content writing across various niches such as health, technology, personal finance, and digital marketing. Known for his ability to simplify complex topics and deliver audience-centric content, he helps brands build authority and trust.